In Chamber Pressure Testing

#11

Are you only measuring pressure from one plug? Plan on using both leading and trailing sensors to see spread times etc?

Only the #1 rotor leading spark plug has a sensor. The sensor plugs are about $1300 each. I want to purchase exhaust and intake port sensors but my computer does not have the capacity at this time.

I would very much like to see testing at the same conditions down to zero split with less advanced timing to see what gives the best net BMEP considering the negative pumping losses on compression and pressure rise time from point of ignition, given mazdas race engine had various multi plug combos I have a feeling for outright power from a given charge that in most conditions a zero split (providing combustion is controlled) should give peak torque/power.

Do you mind stating which model TFX logger you have and what plugs/other sensors you are running. I have an older style DAQ8 PC card type TFX data acquisition unit.

I am assuming they have set up the total power/torque calcs for the rotary on a theoretical base from the geometry (I would guess pressure X area X arm) (with fudged factors for the pressures in the exhaust stroke, unless you are running sensors near/in the exhaust port or manifold) given the sensors cannot see to the end of the power stroke let alone beyond it. With the sensor plug in the leading position it will see the exhaust port open, the trailing will see the intake closing. I might look to purchase my own in the future.

Only the #1 rotor leading spark plug has a sensor. The sensor plugs are about $1300 each. I want to purchase exhaust and intake port sensors but my computer does not have the capacity at this time.

I would very much like to see testing at the same conditions down to zero split with less advanced timing to see what gives the best net BMEP considering the negative pumping losses on compression and pressure rise time from point of ignition, given mazdas race engine had various multi plug combos I have a feeling for outright power from a given charge that in most conditions a zero split (providing combustion is controlled) should give peak torque/power.

Do you mind stating which model TFX logger you have and what plugs/other sensors you are running. I have an older style DAQ8 PC card type TFX data acquisition unit.

I am assuming they have set up the total power/torque calcs for the rotary on a theoretical base from the geometry (I would guess pressure X area X arm) (with fudged factors for the pressures in the exhaust stroke, unless you are running sensors near/in the exhaust port or manifold) given the sensors cannot see to the end of the power stroke let alone beyond it. With the sensor plug in the leading position it will see the exhaust port open, the trailing will see the intake closing. I might look to purchase my own in the future.

#12

I would very much like to see testing at the same conditions down to zero split with less advanced timing to see what gives the best net BMEP considering the negative pumping losses on compression and pressure rise time from point of ignition, given mazdas race engine had various multi plug combos I have a feeling for outright power from a given charge that in most conditions a zero split (providing combustion is controlled) should give peak torque/power.

I second that.

I think that only reasons why most people are scared to run zero split, are not enough accurate Ignition timing of "certain" management systems and/or inability to get strong spark in later crank degrees towards TDC where pressure is higher.

#13

Slides and Liborek,

Do you think that having a split might increase the ignition's capacity or ability to fire the second plug?

I will try more experiments. One without water/meth injection. Some with different splits.

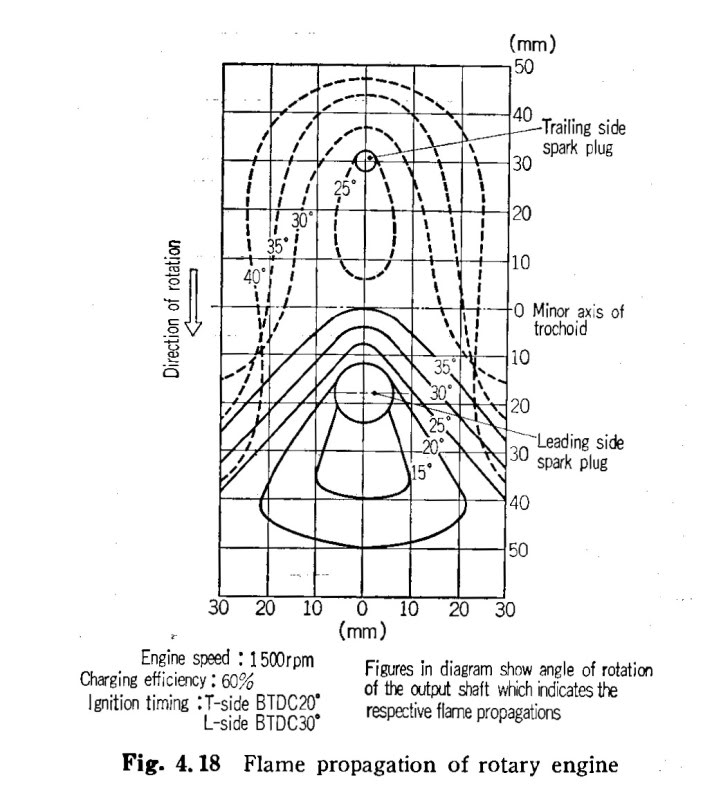

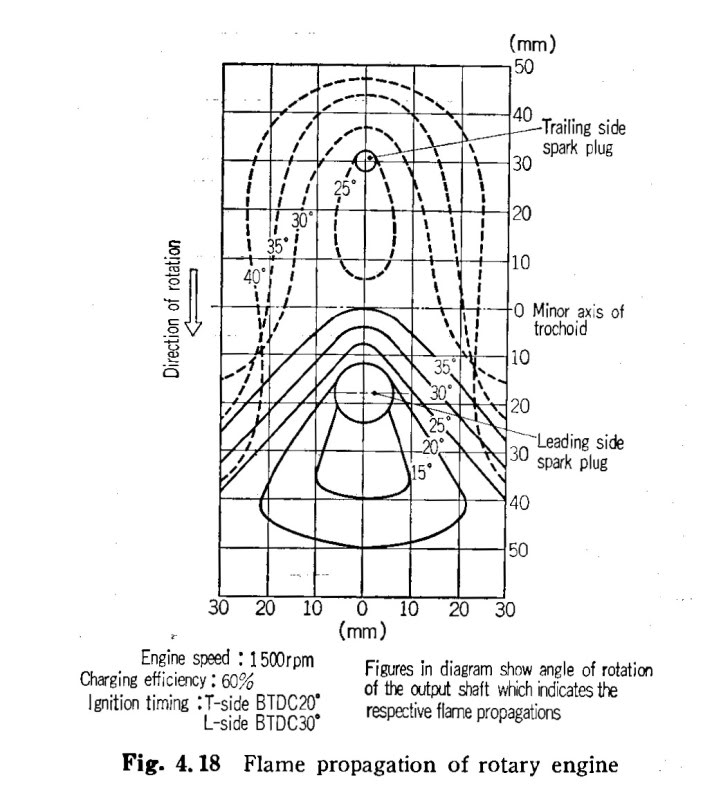

If you notice in the flame propagation graph above that when the leading and trailing flame fronts collide (at about 20º ATDC) that their speed diminishes. Maybe a single plug would make as much power but with poorer fuel economy and a little more pollution.

(Mazda Paper Rotary86v6a4, Fig. 14)

Barry

#14

Slides and Liborek,

Do you think that having a split might increase the ignition's capacity or ability to fire the second plug?

I will try more experiments. One without water/meth injection. Some with different splits.

If you notice in the flame propagation graph above that when the leading and trailing flame fronts collide (at about 20º ATDC) that their speed diminishes. Maybe a single plug would make as much power but with poorer fuel economy and a little more pollution.

(Mazda Paper Rotary86v6a4, Fig. 14)

Barry

Do you think that having a split might increase the ignition's capacity or ability to fire the second plug?

I will try more experiments. One without water/meth injection. Some with different splits.

If you notice in the flame propagation graph above that when the leading and trailing flame fronts collide (at about 20º ATDC) that their speed diminishes. Maybe a single plug would make as much power but with poorer fuel economy and a little more pollution.

(Mazda Paper Rotary86v6a4, Fig. 14)

Barry

I think you need a control to compare to, single leading plug firing mixture, % combustion burn rate will drop off as it progresses in all situations due to the fact that the flame is progressing to areas where more of the energy is taken up by the rotor face & housing (outside the bath area) as opposed to mixture ahead being preheated for ignition at a guess?

It is a shame the sensors cost so much, it would be very nice to see delay time or diffrences between the leading and trailing area to gain a better understanding of these effects.

You could also do some very rough maths looking at rotor face area and flame speed from the results you already have??

#15

Could not edit my previous post

Thought about your comment on speed of combustion again.

The rate of burn speed will obviously have to come down when the flame fronts meet, as you are reducing the flame front total surface area when & where they meet. This effect should not be confused with the effectiveness for total speed of two independent ignitions however, it is merely an observable consequence of the geometry at that time in the process. If the two fronts start together (zero split) and both progress outwards from the holes in the housings (with your swirl/sweeping effects meaning they don't progress in concentric circles as such, so difficult to do conceptualise exactly how the flame will move) you should have the maximum average flame front area, and total rate of increase of area, & rate of combustion over the (shorter) combustion period.

Thought about your comment on speed of combustion again.

The rate of burn speed will obviously have to come down when the flame fronts meet, as you are reducing the flame front total surface area when & where they meet. This effect should not be confused with the effectiveness for total speed of two independent ignitions however, it is merely an observable consequence of the geometry at that time in the process. If the two fronts start together (zero split) and both progress outwards from the holes in the housings (with your swirl/sweeping effects meaning they don't progress in concentric circles as such, so difficult to do conceptualise exactly how the flame will move) you should have the maximum average flame front area, and total rate of increase of area, & rate of combustion over the (shorter) combustion period.

#16

Seems my browser or the forum software won't let me edit once I have shut down and re entered??

You might postulate that a shorter burn time near TDC from "retarded" timing with zero split may result in somewhat less heat transfer to the housing & rotor as there will be less total time spent with a relatively denser & hotter combusted or partially combusted charge too?? Might help to reduce the onset of your pre-ignition on subsequent cycles once you have some continuous load & heat build up??

You might postulate that a shorter burn time near TDC from "retarded" timing with zero split may result in somewhat less heat transfer to the housing & rotor as there will be less total time spent with a relatively denser & hotter combusted or partially combusted charge too?? Might help to reduce the onset of your pre-ignition on subsequent cycles once you have some continuous load & heat build up??

#17

We seem to have lost Lynn Hanover's and Liborek's last comments when the server went down. I waited too long while attempting an intelligent reply.

I think I had replied to Slides comment on burn rate with a vertical shot from Yamamoto's Rotary Engine Book.

Is there a way to get them back?

Barry

I think I had replied to Slides comment on burn rate with a vertical shot from Yamamoto's Rotary Engine Book.

Is there a way to get them back?

Barry

#18

We seem to have lost Lynn Hanover's and Liborek's last comments when the server went down. I waited too long while attempting an intelligent reply.

I think I had replied to Slides comment on burn rate with a vertical shot from Yamamoto's Rotary Engine Book.

Is there a way to get them back?

Barry

I think I had replied to Slides comment on burn rate with a vertical shot from Yamamoto's Rotary Engine Book.

Is there a way to get them back?

Barry

Here is some of it.

Wankel collected thousands of patent drawings, looking for a device or mechanism that could be used as an IC engine with pure rotary motion. He found such a drawing that had most of what he needed, and set about altering the design to attain his goal.

He convinced NSU, a Moped manufacturer to produce this engine. Two prototype sizes were built and tested. Engineers at NSU saw that the engine was not at all practical (the rotor housing rotated at 2/3 crank speed) the spark plugs in the rotor face? And many external sliding seals.

Behind Wankel's back the NSU people used the basic design, but reduced the complexity be holding the rotor housing stationary, they built the basic engine you see today. Wankel was very unhappy.

When NSU tried to patent their new engine, they were turned down. A similar device already existed (remember where Wankel got his ideas).

The patent was held by Bernard Maillard who worked for Aldoph Saurer a truck manufacturer. He gifted the patent rights to NSU because his design had the seals stationary in the waist of the Trochoid.

(a gift worth millions)

So it is a Maillard rotary, or a Saurer rotary, but hardly a Wankel.

Data recovery at this time was close to stone age. Strip chart recorders were the bleeding edge of

technology. A stylus scribbling lines on a 3" wide strip of paper was it. Since then we have come 100 years worth of advancement. We can recover in minute detail, and with painful accuracy any parameter you can imagine. And since it is possible, lots of people and organizations do it every day.

The license holders were required to share findings with all other license holders. So the whole of data collection could be mountains high, and although many facts were recovered by more than one license holder and thus duplicated, the effect is that a lot of ground was covered in very few years.

It is also probable that publication was delayed, and, or, data was released well after better data had been recovered, so that each entity would not have to face their own research in a competitors product.

They all being human and so on.

All of the data in Kenichi Yamamoto's book was collected before the 80s.

The pictogram of the burn fronts is the pattern for 1,500 RPM. The effort was to develop a car engine, and car engines spend most of their lives below 2,200 RPM. Cars need only about 25 HP to move at freeway speeds. So interest in the lower RPM was where the interest was concentrated.

I doubt the pattern is similar at 8,000 RPM. Note that the Lemans engine had three spark plugs even though they used modest peak RPM. This to improve fuel mileage AND performance. If you plan to recover high output from your rotary, it is almost mandatory that you install a high output CD ignition system like the Mallory HiFire or MSD6AL or similar.

Ignition timing. There are some items to consider. The object is to have the pressure peak at about 50 degrees after TDC. This gives the highest mechanical advantage over the crank shaft. For loaded engines this true. In some situations like no load, or light load you may need to alter the timing without regard to where the highest pressure ends up. In no load spool down from a loaded or just higher RPM, you may need up to 45 degrees of advance. You will have less than idle fuel volume. A high amount of exhaust gas mixing, and lowered chamber temps. The fuel droplets will be far apart, and many will have clumps of exhaust gas clinging to them. With no throttle opening, a compression ratio of nil.

Well below atmospheric (14.7 pounds at sea level)

So the mixture is difficult (misfires) to light. When you are successful the burn will move along very slowly, so the very early timing is of no concern as far as damage or temperature.

Under power the NA engine does fine with 25 degrees up to 9,000 RPM. Above that maybe 27 degrees.

In the boosted engine the effective compression ratio changes wildly from second to second, and thus burn rate changes as well. The effort is still to peak at about 50 degrees ATDC but the problem becomes much more complex. Smaller variations in inlet air temperature make for bigger variations in burn rate. Same for variations in oil temperature and coolant temperature.

Racing Beat says that they use 10 degrees of total advance for development and 12 degrees for racing in boosted engines. These folks have filled dumpsters full of destroyed development engines so you wouldn't have to. Download their catalog /tech manual.

RPM.

If you limit RPM with load, like full throttle in too tall a gear, you must have an ignition system that can remove advance, With a fixed, or unsophisticated system you will be over advancing the timing.

Because while the burn rate will be the same, the peak pressure will occur well before 50 degrees.

This is a big help if your plan was to destroy the engine. If you need lots of power rev the engine into its working range before loading it.

Timing split.

The idea is to help the engine with poor fuel burn at low and medium speeds. Just so you can sell the engines in California. It is of little value at high engine speeds, and at high cylinder pressures starts to look like detonation.

Racing beat says no split timing on boosted engines.

Some people shut off the trailing ignition during big Nitrous injections to avoid detonation.

Just some thoughts.

Lynn E. Hanover

#20

Yes Lynn, thank you very much for your valued input.

Zero split on boosted engines? This scares me. But so does high boost and many are doing it.

I am thinking about repeating the tests with water and without. The tests so far were done with 50/50 meth-water.

Barry Bordes